Structure currently available for directional retroreflective There are two main. One is type retroreflective microprism retroreflective array, and the other is a glass bubble type retroreflective retroreflective. Microprism array type retroreflective microprismatic retroreflective material using molding techniques required to accomplish; the latter is composed of glass microspheres. Glass microspheres are a special kind of glass sphere diameter is generally around 40 ~ 800μm, in the manufacture of traffic signs, retroreflective materials has an extremely wide range of applications. The size of its index of refraction, and directly affects the retroreflective properties of glass microspheres. Therefore, the refractive index is an important parameter and determines the impact glass microspheres optical properties. Glass bubble type retroreflective material is currently scheduled to be available for directional signage has reflective properties, particularly the traffic signs have been widespread use of retroreflective material. This material is manufactured utilizing the principle of geometrical optics, and then plated with a certain reflectivity and having special "logo or statement" the film, so that the reflected light toward the direction of the incident light source can be retroreflective. This flag is illuminated by means of a car or outside lights and other light sources, so that the driver can see at night pattern sign surface, greatly beneficial to road safety. In addition, this type of reflective signs can also be used in the field uniforms, reflective isolation belt, reflective signs, anti-cursor line, reflective number plates and other facilities as well as tunnels and underground construction.

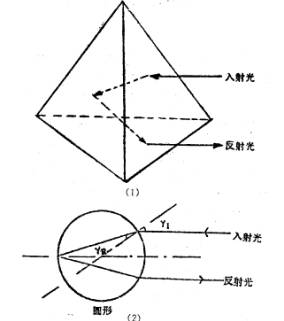

Structure currently available for directional retroreflective There are two main. One is type retroreflective microprism retroreflective array, and the other is a glass bubble type retroreflective retroreflective. Microprism array type retroreflective microprismatic retroreflective material using molding techniques required to accomplish; the latter is composed of glass microspheres. Glass microspheres are a special kind of glass sphere diameter is generally around 40 ~ 800μm, in the manufacture of traffic signs, retroreflective materials has an extremely wide range of applications. The size of its index of refraction, and directly affects the retroreflective properties of glass microspheres. Therefore, the refractive index is an important parameter and determines the impact glass microspheres optical properties. Glass bubble type retroreflective material is currently scheduled to be available for directional signage has reflective properties, particularly the traffic signs have been widespread use of retroreflective material. This material is manufactured utilizing the principle of geometrical optics, and then plated with a certain reflectivity and having special "logo or statement" the film, so that the reflected light toward the direction of the incident light source can be retroreflective. This flag is illuminated by means of a car or outside lights and other light sources, so that the driver can see at night pattern sign surface, greatly beneficial to road safety. In addition, this type of reflective signs can also be used in the field uniforms, reflective isolation belt, reflective signs, anti-cursor line, reflective number plates and other facilities as well as tunnels and underground construction.Beam irradiated to the surface of the material of the most common phenomenon of two specular reflection and diffuse reflection. And return it with a reflective film with more than two different light reflections reflective properties that return reflective properties, which enables the opposite direction parallel to the incident light incident along with reverse return. Since the reflectivity of the glass microspheres themselves small, it should be plated after the glass microspheres reflective film, in order to improve their directional retroreflective performance.

From the theoretical analysis of the retro-reflective glass microspheres directional principle, the use of near-axis light refraction spherical glass microspheres to achieve the theoretical analysis of the retro-reflective refractive index, combined with the actual usage, the increase in the maximum possible return on the basis of reflection, to discuss the the distance to the main axis of the incident light and the regression relationship between the light and the angle of the incident light, and thus determine the refractive index of the range to achieve maximum reflective glass microspheres of 1.80 to 1.95, the findings development of retroreflective signs of has important theoretical significance.