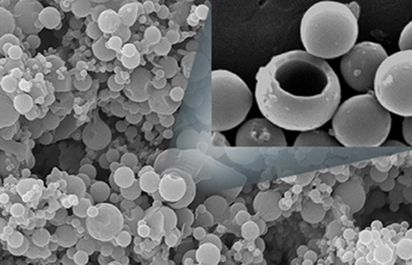

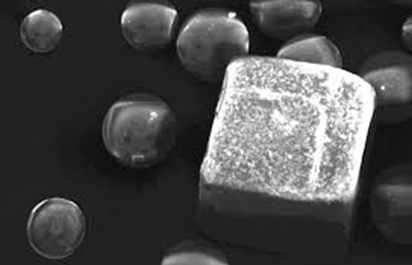

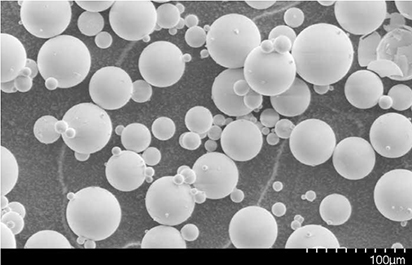

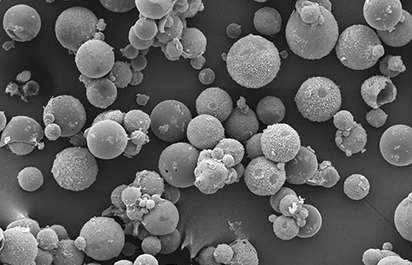

Des sphères plus fortes en verre creux creuses s'attaquent au moulage par injection

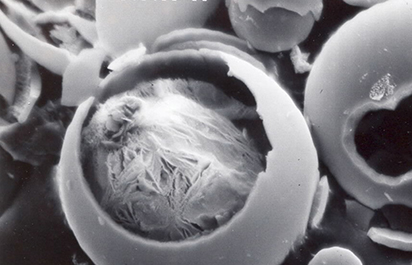

La dernière microsphère de verre creuse, de qualité Additifs de performance, possède la plus haute résistance à la compression au monde pour un tel produit....

Learn more >